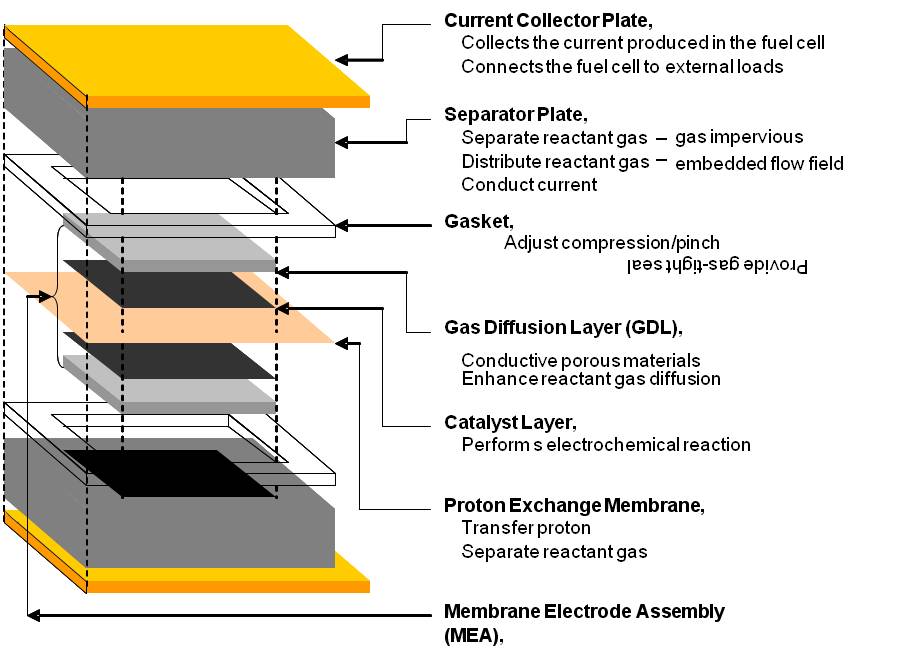

In order for a PEM fuel cell to operate, a Proton Exchange Membrane is needed that will carry the hydrogen ions, proton, from the anode to the cathode without passing the electrons that were removed from the hydrogen atoms. These polymer membranes that conduct proton through the membrane but are reasonably impermeable to the gases, serve as solid electrolytes (vs. liquid electrolyte) for variety of electrochemical applications, and are commonly known as Proton Exchange Membrane and/or Polymer Electrolyte Membranes (PEM). These membranes have been identified as one of the key components for various consumer related applications for fuel cells, e.g. automobiles, back-up power, portable power etc. Due to its application for many consumer markets, the technology keeps on evolving to make these membranes suitable for longer duration, and even high temperature operations.

For PEM fuel cell and electrolyzer applications, a polymer electrolyte membrane is sandwiched between an anode electrode and a cathode electrode. During electrochemical reaction, oxidation reaction at the anode generates protons and electrons; reduction reaction at the cathode combines protons and electrons with oxidants to generate water. To complete the electrochemical reaction, the proton exchange membrane plays a critical role that conducts protons from anode to cathode through the membrane. The proton exchange membrane also performs as a separator for separating anode and cathode reactants in fuel cells and electrolyzers.

One of the most common and commercially available PEM membrane is, DuPont’s Nafion membranes. These are widely used for PEM fuel cells and can be identified based on the variety of thickness and specific application. Nafion® 117, Nafion® 115, Nafion® NR212 Nafion® NR211 membranes are non-reinforced films, and last numbers apply to their various thickness dimensions.

Nafion® XL membranes are newly developed reinforced membranes that enhance the chemical stability of Nafion® membranes. The mechanical durability and enhanced chemical stability of the Nafion® XL membrane are the result of an advanced stabilization system that increases mechanical strength and provides resistance to peroxide attack, resulting in improved membrane life and performance.

Nafion® HP membranes are an ultra-thin membrane. These membranes are reinforced and designed for lower relative humidity environments and high operating temperature. The reinforcement improves the membrane’s handling and physical properties. When the reinforcement is combined with the chemically stabilized polymer, the Nafion® HP membrane exhibits both substantially lower fluoride ion release and longer operating durability under challenging fuel cell conditions.