Noise based corrosion research using conventional electrochemical methods focus on the fact that the initial redox processes are related to the charge transfer of the metal dissolution deposition processes. Distinct areas of the object surface can be viewed as local galvanic elements that contribute to the total measured potential. Since many of these local elements are superimposed, the fluctuation of the potential (and the current, if the electrode is polarized) is low. Traditional electrochemical methods are based on this „steady state" behavior. However, inhomogeneous corrosion attack, which is particularly important in the nucleation phase, does not conform to these conditions. Traditional methods such as impedance or Tafel techniques will fail for such inhomogeneous corroding objects, because the measurement signals become more and more noisy. In this case noise measurements quantify these discrete events that are disturbing the continuous methods.

For analysis, it is of great value to measure both current and potential noise. The problem is that measurement of current noise essentially requires a short circuit condition, whereas potential noise must be measured with a high impedance load. The standard method for solving this problem is to measure two identical systems, one under open circuit, the other under short circuit condition. A common experimental arrangement uses three identical electrodes, where one pair acts as a current noise source under short-circuit conditions, the second as a potential noise source under open circuit condition. One electrode acts as a common electrode.

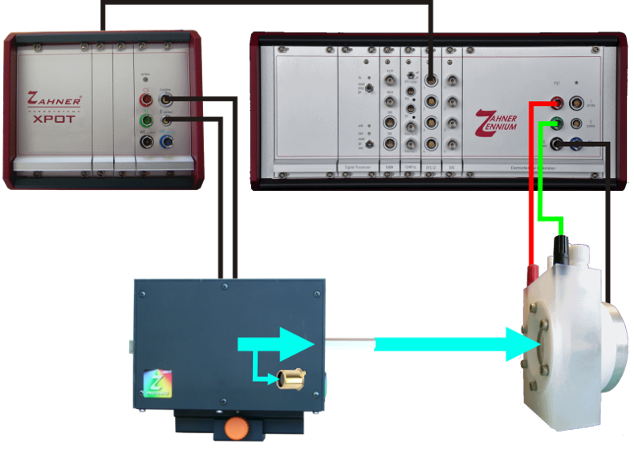

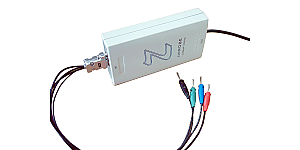

This arrangement is often used in monitoring applications, and can be set up with a ZENNIUM electrochemical workstation equipped with EPC42 + NProbe. However, this method has a significant disadvantage in that the measured current and potential noise do not come from the same electrochemical system. Even though it is assumed that the corrosion behavior of both systems is identical, the current and the potential are not correlated. This means that only the scalar rms values can be related, and vector operations like power calculation are meaningless.

There is a solution for the problem, based on the fact that corrosion-related noise is observed mainly in the low frequency range. To a first approximation, the noise source may be described as a low frequency noise oscillator in series with a source resistance. Therefore it is possible to sample both current and potential signals by rapid switching between the two modes (open circuit and short circuit). If the switching/sampling frequency is high relative to the highest noise frequency of interest, this technique works without loss of information.

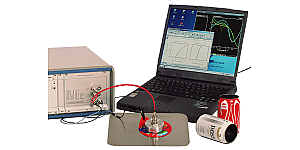

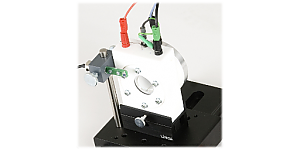

CorrElNoise, developed by the specialists at Zahner, is based on these principles. CorrElNoise stands for the measurement of CORRelated ELectrochemical current and potential NOISE coming from the same source. The method is available both as a plug-in for the IM6 and as a stand-alonesystem. It enables the user to record current, potential and power noise in the frequency range from DC up to about 5 Hz. Furthermore CorrElNoise benefits from the chopper principle. This means that electronic offset and drift problems, as well as line frequency interference, are automatically suppressed.

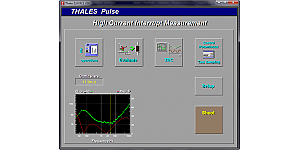

As noise measurements normally have a long acquisition time there is a lot of data to be handled. The NOISE software allows to save measurement data in two ways: Normally the software reduces the flood of data by a factor of 260. Then you have access to the most often used analysis mode, the frequency spectrum of the noise signal. In addition the time-domain signal can be saved so that any other analysis method can be applied after the acquisition. Time-domain data are compressed with a factor of 8.